Underground transformer

Category:

Keywords:

Underground transformer

1. Product Introduction:

The underground box-type substation adopts a split modular structure, consisting of an underground transformer, prefabricated pit, and a low-voltage distribution cabinet with a lightbox structure. The high-voltage and transformer units are buried below the ground surface, occupying no surface area, greatly reducing high-voltage hazards and electromagnetic radiation. Above ground is a media advertising lightbox that hides the low-voltage distribution cabinet inside, becoming a major highlight in beautifying the city. Its surface footprint is only 1/5 that of traditional European-style box transformers. Additionally, the media advertising lightbox uses energy-saving, long-life LED light sources, saving 80% more power than traditional light sources. Therefore, it is very suitable for street lighting, green belts, airports, commercial centers, municipal squares, tourist attractions, highways, residential communities, and other places. It is a new type of energy-saving and environmentally friendly distribution network method, aligning well with the national advocacy for building a "resource-saving society."

2. Standards:

2.1 GB/T 17467 High Voltage/Low Voltage Prefabricated Substation

2.2 DL/T 537 Guidelines for Selection of High Voltage/Low Voltage Prefabricated Box-type Substations

2.3 JB/T 10217 Modular Transformer

2.4 GB7251.1 Low Voltage Complete Equipment and Control Equipment Part 1 Type Tests and Partial Type Tests of Complete Equipment

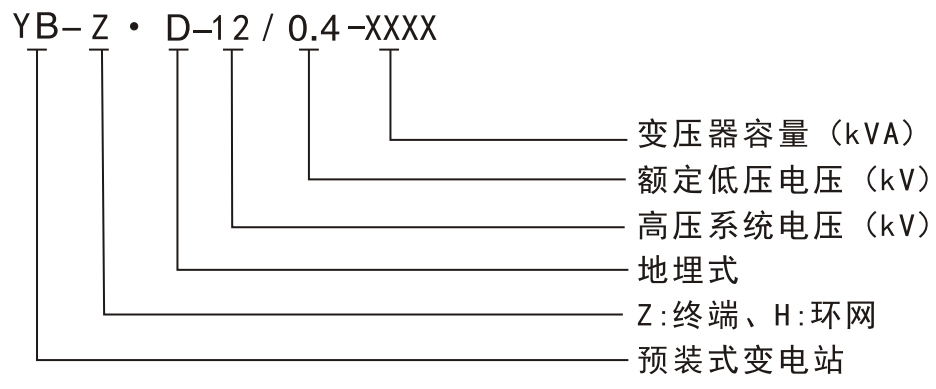

3. Model and Meaning:

4. Product Features:

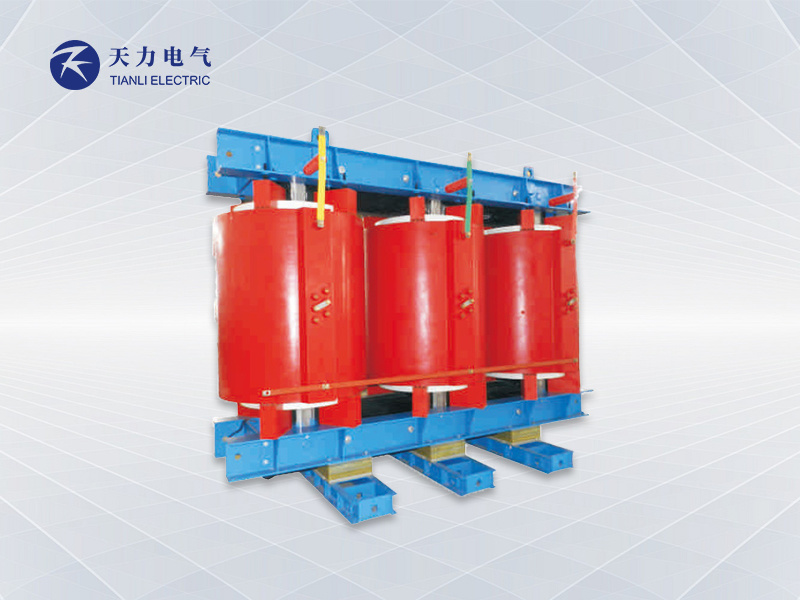

4.1 Reduced On-site Construction: The underground box-type substation adopts a split modular structure, consisting of an underground transformer, prefabricated pit, and a low-voltage distribution cabinet with a lightbox structure. All products are 100% pre-assembled in the factory, greatly reducing on-site construction work.

4.2 Energy Saving and Low Operating Costs: The transformer uses S13 or SH15 amorphous alloy transformers, whose no-load losses are reduced by 30% and 80% respectively compared to the S11 series. The high-voltage unit and transformer are installed in a prefabricated pit buried below the ground surface, with only the low-voltage distribution cabinet placed on the prefabricated foundation in a lightbox structure, ensuring higher safety. Its surface footprint is only 1/5 that of traditional European box transformers, allowing it to be closer to the load center, saving low-voltage line losses and low-voltage cable investment.

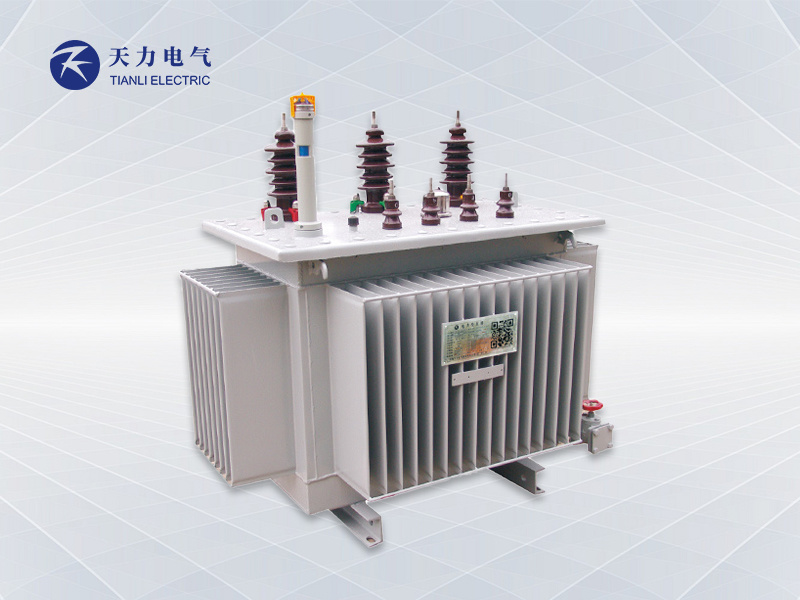

4.3 Comprehensive Protection: The high-voltage unit uses two-position or four-position oil-immersed load switches built into the underground transformer. The transformer uses plug-in fuses for full-range protection, which are easy to replace. The high-voltage incoming line uses touchable, fully sealed, fully shielded cable plug-in components, ensuring high safety.

4.4 Flood-Resistant Operation: The transformer box adopts a fully welded structure. The high and low voltage incoming and outgoing lines use double sealing structures to ensure no leakage or defects in the transformer, allowing short-term flood operation. To prevent long-term flooding caused by surface water backflow during extreme weather such as floods, the bottom of the prefabricated pit is equipped with a sump and automatic drainage device below the box installation surface. Through a liquid level sensor, accumulated water inside the box can be automatically and thoroughly drained, ensuring electrical safety.

4.5 Unique Ventilation and Heat Dissipation Design: Considering the special underground heat dissipation conditions, the transformer uses segmental radiators, and the prefabricated pit uses a corrugated plate structure to increase radiation and conduction area. Sufficient ventilation and heat dissipation holes are set at the bottom of the advertising lightbox to ensure natural ventilation and heat dissipation conditions for the transformer. A duct-type ventilation and heat dissipation device is also equipped, which can automatically or manually start a strong wind cooling device when the transformer is overloaded, ensuring low-temperature operation.

4.6 Safe and Reliable: The high-voltage part is completely buried below the ground surface. The low-voltage cabinet uses a double protective door structure. Even if the outer door of the lightbox is damaged, the protection level of the inner door of the low-voltage cabinet is not less than IP33. The low-voltage cabinet is equipped with an anti-theft alarm device that automatically alarms when the lightbox shell is impacted or damaged, effectively protecting personal and electrical safety.

4.7 Intelligent and Remote Communication Capable: When equipped with a temperature controller with a communication interface and a GPRS load control terminal device, remote monitoring, data collection, and data analysis can be realized. It can monitor the temperature, load, power factor, and other variables of each equipment point in real time, reducing operation and maintenance costs.

4.8 Beautiful Appearance and Corrosion Resistance: The prefabricated pit and underground transformer adopt multiple anti-rust processes, with surfaces sprayed with marine ship special anti-rust paint, providing excellent corrosion resistance. The lightbox shell uses 304 stainless steel material, effectively avoiding rust after outdoor equipment anti-corrosion coatings are damaged. The pit cover plate uses reinforced concrete structure covered with pavement bricks, blending well with the surrounding environment.

4.9 Low Noise and No Radiation: Since the high-voltage unit and transformer unit of the underground box transformer are buried below the ground, transformer noise at night is effectively reduced. The metal prefabricated pit forms an effective electromagnetic shield, blocking the transformer's electromagnetic radiation and eliminating physiological and psychological effects on people.

5. Operating Conditions:

5.1 Ambient Air Temperature: Maximum temperature: +40°C, average temperature of the hottest month: +30°C, maximum annual average temperature: +20°C, minimum temperature: -20°C (outdoor), maximum daily average temperature difference: 25K.

5.2 Altitude: ≤1000m (altitude correction required above this altitude).

5.3 Humidity: Daily average relative humidity not exceeding 95%, monthly average relative humidity not exceeding 90%.

5.4 Wind Pressure: Not exceeding 700Pa.

5.5 Installation Environment:

(1) Installation site inclination: <3°.

(2) Earthquake resistance: Ground horizontal acceleration: less than 3.0m/s², ground vertical acceleration: less than 1.5m/s², safety factor above 1.67.

(3) Surrounding air should be free of corrosive or flammable gases, water vapor, or obvious pollution, and no severe vibration.

5.6 For special operating environments such as high humidity, large temperature variations, pollution below level I1, and vibration, special design treatments should be applied.

Technical Parameter Table of YB-D Series Underground Box-type Substation

|

Serial Number |

Item |

Unit |

Data |

|

|

1 |

Rated Voltage |

High Voltage Side |

kV |

10, 6 |

|

Low Voltage Side |

kV |

0.4 |

||

|

2 |

Higher Operating Voltage |

kV |

12, 7.2 |

|

|

3 |

Rated Frequency |

Hz |

50 |

|

|

4 |

Rated Capacity |

kVA |

30, 50, 63, 80, 100, 125, 160, 200, 250, 315, |

|

|

5 |

Rated Short-time Power Frequency Withstand Voltage |

kV |

35KV/5kV, 1min; 25kV/5kV, 1min |

|

|

6 |

Rated Lightning Impulse Withstand Voltage |

kV |

75, 60 |

|

|

7 |

Power Frequency Withstand Voltage of Low Voltage Electrical Components |

kV |

2.5KV/1min |

|

|

8 |

Rated Short-time Withstand Current of High Voltage Load Switch |

kA |

20kA/2S, 12.5kA/2S, |

|

|

9 |

Rated Peak Withstand Current of High Voltage Load Switch |

kA |

50, 31.5 |

|

|

10 |

Insert-type Fuse Breaking Current |

kA |

2 |

|

|

11 |

Voltage Regulation Method |

|

No-load Voltage Regulation ±2×2.5% or ±5% |

|

|

12 |

Transformer Noise |

dB |

≤52 |

|

|

13 |

Protection Level |

|

Transformer: IP68, Low Voltage Cabinet: IP33 |

|

|

14 |

High Voltage Incoming and Outgoing Line Method |

|

Cable |

|

|

15 |

High Voltage Distribution Scheme |

|

Ring Network, Terminal |

|

Technical Parameter Table of YB-D Series Underground Box-type Substation S13 Transformer

|

Transformer Capacity |

High Voltage |

Low Voltage |

Connection Group Number |

Short-circuit Impedance |

No-load Loss (W) |

Load Loss (W) |

No-load Current (%) |

|

30 |

6 |

0.4 |

Dyn11 Yyn0 |

4 |

80 |

630/600 |

0.5 |

|

50 |

100 |

910/870 |

0.5 |

||||

|

80 |

130 |

1310/1250 |

0.45 |

||||

|

100 |

150 |

1580/1500 |

0.45 |

||||

|

160 |

200 |

2310/2200 |

0.4 |

||||

|

200 |

240 |

2730/2600 |

0.4 |

||||

|

250 |

290 |

3200/3050 |

0.35 |

||||

|

315 |

340 |

3830/3650 |

0.35 |

||||

|

400 |

410 |

4520/4300 |

0.35 |

||||

|

500 |

480 |

5410/5150 |

0.3 |

||||

|

630 |

570 |

6200 |

0.25 |

||||

|

4.5 |

|||||||

|

800 |

700 |

7500 |

0.18 |

||||

|

1000 |

830 |

10300 |

0.17 |

||||

|

1250 |

970 |

12000 |

0.17 |

||||

|

1600 |

1170 |

14500 |

0.16 |

Note: Due to continuous product improvements, the data provided in this sample is for reference only; please contact our company in time to obtain the latest dimensions.

Recommended Products

Online message

Leave a message online and get a free product quotation. We will arrange a specialist to contact you as soon as possible