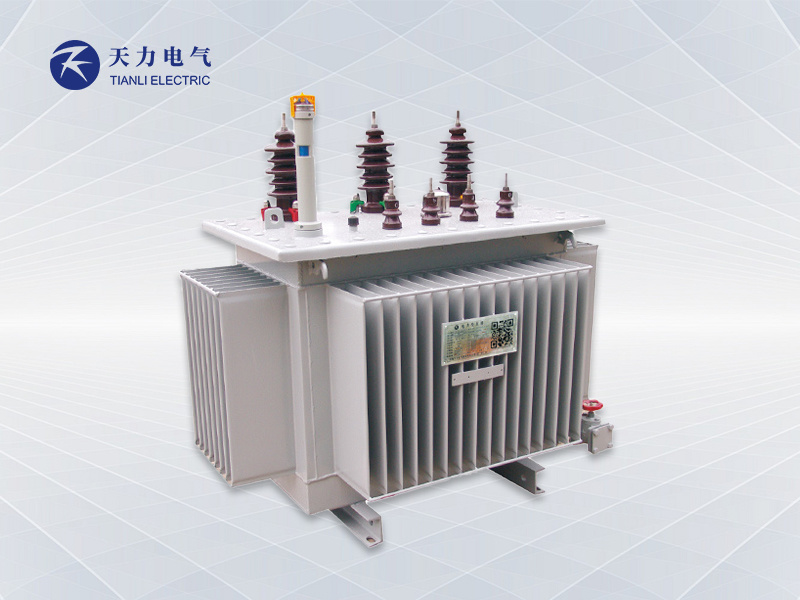

S(B)H15(21,25)-M series amorphous alloy oil-immersed transformer

Category:

Keywords:

S(B)H15(21,25)-M series amorphous alloy oil-immersed transformer

25)-M series amorphous alloy oil-immersed transformer

S(B)H15(21

oil immersed transformer

oil-immersed transformer

1. Product Introduction

Amorphous alloy is a new type of energy-saving material produced by rapid quenching technology. Its physical state is characterized by metal atoms arranged in a disordered amorphous structure. It is completely different from the crystalline structure of silicon steel, making it easier to magnetize and demagnetize. The thickness of its core sheets is extremely thin, only 0.025mm, less than 1/10 of commonly used silicon steel sheets. This new material used in transformer cores features high saturation magnetic induction, low loss, low excitation current, and good temperature stability. The core adopts a single-frame or three-phase five-column wound core. The core is clamped with thin plates or formed frame structures. The high and low voltage windings have a rectangular structure. Amorphous alloy transformers have low no-load loss, strong short-circuit resistance, advanced structure, energy-saving and environmental protection advantages, aligning with the Chinese government's industrial policy of "saving resources, protecting the environment, and building a resource-saving society." It is currently an ideal energy-saving distribution transformer.

2. Standards:

2.1 IEC60076-1 Power Transformers

2.2 GB/T1094.1 Power Transformers

2.3 GB/T25446 Oil-immersed Amorphous Alloy Core Distribution Transformer Technical Parameters and Requirements

2.4 JB/T10088 6kV~500kV Power Transformer Noise Level

2.5 GB20052-2020 Power Transformer Energy Efficiency Limits and Energy Efficiency Grades

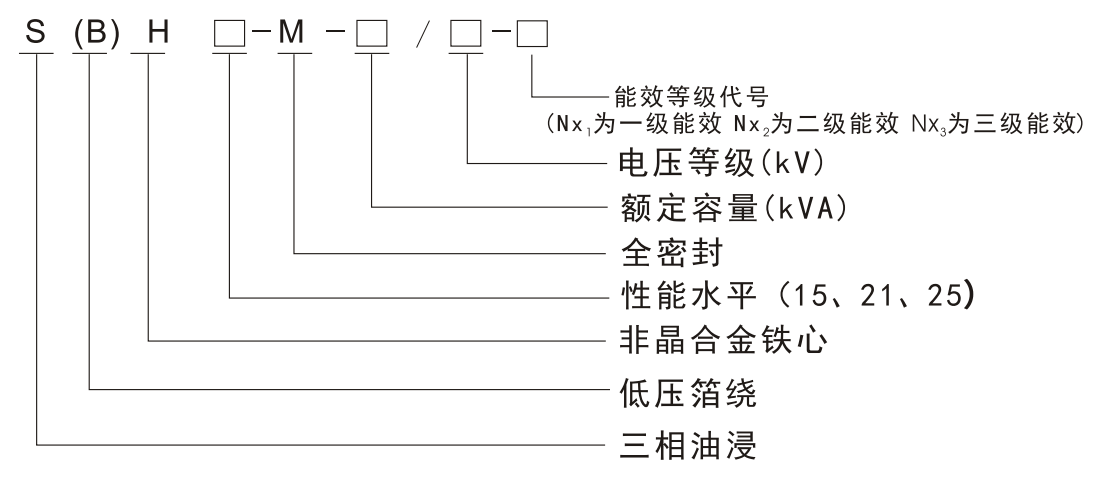

3. Model Description:

4. Product Features:

4.1 The core is wound with amorphous alloy strip material, reducing no-load loss by about 75% compared to S11 type transformers, and no-load current decreases by about 80%.

4.2 The low voltage winding uses copper foil to enhance the transformer's short-circuit withstand capability.

4.3 The connection group adopts D.yn11 to reduce harmonic impact on the power grid and improve power supply quality.

4.4 The enclosure uses a fully sealed structure to extend service life and requires no maintenance.

4.5 Vacuum oil filling is used to completely eliminate bubbles in the winding, ensuring stable insulation performance.

4.6 Each transformer undergoes a full-wave lightning impulse test meeting national standards for peak voltage before leaving the factory to ensure completely reliable operation.

Technical Parameters of 10kV Grade S(B)H15(21, 25) Series Amorphous Alloy Oil-immersed Transformers

|

Transformer |

High Voltage |

High Voltage Tap Range |

Low Voltage |

Rated |

Connection Group |

No-load Loss (W) |

Load Loss (W) |

No-load |

Short-circuit |

Gauge |

Dimensions |

Weight |

||||

|

S15 |

S21 |

S25 |

S15 |

S21 |

S25 |

|||||||||||

|

30 |

6 |

5 2× 2.5 |

0.4 |

50 |

D,yn11 Y,yn0 |

33 |

33 |

25 |

630/600 |

535/510 |

510/480 |

0.6 |

4 |

550x550 |

915x850×830 |

480 |

|

50 |

43 |

43 |

35 |

910/870 |

780/745 |

735/700 |

0.5 |

550×550 |

1040x775×870 |

510 |

||||||

|

80 |

60 |

60 |

50 |

1310/1250 |

1120/1070 |

1060/1010 |

0.5 |

550x550 |

1060×825×910 |

565 |

||||||

|

100 |

75 |

75 |

60 |

1580/1500 |

1350/1285 |

1270/1215 |

0.45 |

550x550 |

1140x830x855 |

580 |

||||||

|

160 |

100 |

100 |

80 |

2310/2200 |

1975/1880 |

1870/1780 |

0.45 |

660×820 |

1125×880x1000 |

900 |

||||||

|

200 |

120 |

120 |

95 |

2730/2600 |

2330/2225 |

2210/2100 |

0.4 |

660×820 |

1235×895×1020 |

950 |

||||||

|

250 |

140 |

140 |

110 |

3200/3050 |

2735/2610 |

2590/2470 |

0.4 |

660×820 |

1290×895x1065 |

1240 |

||||||

|

315 |

170 |

170 |

135 |

3830/3650 |

3275/3120 |

3100/2950 |

0.35 |

820×820 |

1375x835x1110 |

1280 |

||||||

|

400 |

200 |

200 |

160 |

4520/4300 |

3865/3675 |

3660/3480 |

0.35 |

820×820 |

1415×915×1245 |

1405 |

||||||

|

500 |

240 |

240 |

190 |

5410/5150 |

4625/4400 |

4380/4170 |

0.3 |

820×820 |

1360×1035x1175 |

1530 |

||||||

|

630 |

320 |

320 |

250 |

6200 |

5300 |

5020 |

0.25 |

4.5 |

820×820 |

1530x1115x1305 |

2320 |

|||||

|

800 |

380 |

380 |

300 |

7500 |

6415 |

6075 |

0.18 |

660×820 |

1875x1205x1360 |

3120 |

||||||

|

1000 |

450 |

450 |

360 |

10300 |

8800 |

8340 |

0.17 |

660×820 |

2035x1515x1355 |

3950 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

1250 |

|

|

|

|

|

530 |

530 |

425 |

12000 |

10260 |

9720 |

0.16 |

|

660×820 |

2135x1515x1430 |

4770 |

|

1600 |

630 |

630 |

500 |

14500 |

12400 |

11745 |

0.15 |

820x1070 |

2255x1535x1500 |

5590 |

||||||

|

2000 |

720 |

710 |

550 |

18300 |

14800 |

14000 |

0.14 |

5 |

820×1070 |

2380×1600×1580 |

6410 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

2500 |

|

|

|

|

|

865 |

860 |

670 |

21200 |

16300 |

15450 |

0.13 |

|

820x1070 |

2500x1680x1650 |

7580 |

Note: Due to continuous product improvements, the data provided in this catalog is for reference only; for the latest dimensions, please contact our company in time.

Recommended Products

Online message

Leave a message online and get a free product quotation. We will arrange a specialist to contact you as soon as possible