S13(20,22)-M.RL series three-dimensional triangular wound core transformer

Category:

Keywords:

S13(20,22)-M.RL series three-dimensional triangularwoundcoretrans

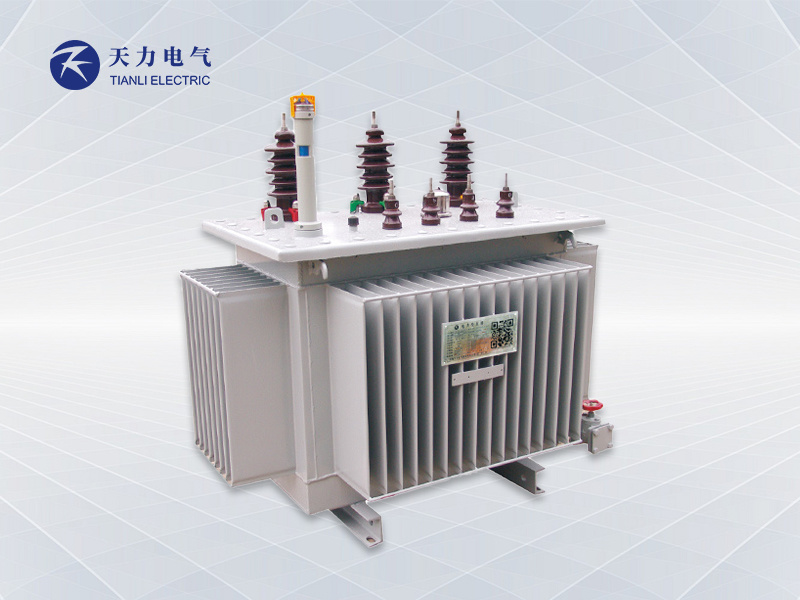

Oil-immersed power transformer

oil immersed power transformer

1. Product Introduction:

10kV class S13(20, 22)-M series energy-saving oil-immersed distribution transformers use high-quality, high magnetic conductivity cold-rolled grain-oriented silicon steel sheets for the core, stacked with 45° full diagonal joints. This series features excellent performance, low operating noise, and compact structure. It is a new generation of environmentally friendly, high-efficiency energy-saving products suitable for urban and rural power grid renovation in industrial and mining enterprises, and is especially suitable for compact prefabricated box-type substations.

2. Standards:

2.1 IEC60076-1 Power Transformers

2.2 GB/T1094.1 Power Transformers

2.3 GB/T6451 Technical Parameters and Requirements for Oil-immersed Power Transformers

2.4 JB/T10088 6kV~500kV Power Transformer Noise Level

2.5 GB20052-2020 Power Transformer Energy Efficiency Limits and Energy Efficiency Grades

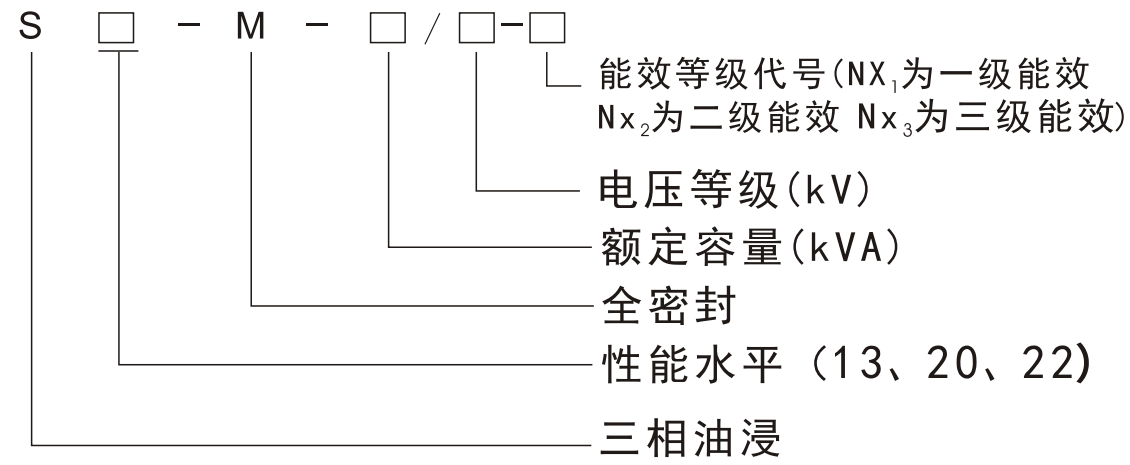

3. Model and Meaning:

4. Structural Features:

Core: Entirely made of high-quality, high magnetic conductivity grain-oriented cold-rolled silicon steel sheets with full diagonal, hole-free binding structure. The core is multi-stage stepped with three, five, or seven joints, resulting in low no-load loss and low noise.

Windings: Made of high-quality QQ acetal enameled round copper wire, flat copper wire drawn from oxygen-free copper rods, or copper foil. The forms include cylindrical, continuous, new spiral, and split types, providing sufficient electrical strength, mechanical strength, heat dissipation capability, and short-circuit resistance.

Oil Tank: Welded from high-quality steel plates, available in oval or rectangular shapes. Heat dissipation elements use plate-type radiators or corrugated oil tanks. The oil tank undergoes reliable sealing tests in the factory. Both internal and external surfaces are treated with acid washing and phosphating, followed by three coats on the bottom and one on the sides of paint spraying, making it both corrosion-resistant and aesthetically pleasing.

Technical Parameters of 10kV Class S13 Series Energy-saving Oil-immersed Transformer

|

Transformer |

High Voltage |

High Voltage Tap Range (%) |

Low Voltage |

Rated |

Connection Group |

No-load |

Load |

No-load Current |

Noise Level |

Short Circuit |

Gauge |

Dimensions |

Weight |

|

30 |

6 |

52× |

0.4 |

50 |

D,yn11 Y,yn0 |

80 |

630/600 |

0.5 |

43 |

4.0 |

400x400 |

830x650x950 |

380 |

|

50 |

100 |

910/870 |

0.5 |

43 |

400×400 |

850×680×960 |

420 |

||||||

|

80 |

130 |

1310/1250 |

0.45 |

44 |

400x400 |

870×700x1010 |

520 |

||||||

|

100 |

150 |

1580/1500 |

0.45 |

44 |

400x400 |

900×720x1020 |

580 |

||||||

|

160 |

200 |

2310/2200 |

0.4 |

46 |

550×550 |

1190×770x1090 |

790 |

||||||

|

200 |

240 |

2730/2600 |

0.4 |

47 |

550x550 |

1260×850x1120 |

880 |

||||||

|

250 |

290 |

3200/3050 |

0.35 |

48 |

550x550 |

1300×860x1140 |

1020 |

||||||

|

315 |

340 |

3830/3650 |

0.35 |

48 |

660x660 |

1370×910x1160 |

1220 |

||||||

|

400 |

410 |

4520/4300 |

0.35 |

48 |

660x660 |

1400×920×1220 |

1430 |

||||||

|

500 |

480 |

5410/5150 |

0.3 |

49 |

660x660 |

1530×1000×1280 |

1730 |

||||||

|

630 |

570 |

6200 |

0.25 |

49 |

4.5 |

660x660 |

1610x1060x1320 |

2100 |

|||||

|

800 |

700 |

7500 |

0.18 |

50 |

660x820 |

1670x1120x1380 |

2480 |

||||||

|

1000 |

830 |

10300 |

0.17 |

50 |

660x820 |

1720×1160×1400 |

2880 |

||||||

|

1250 |

970 |

12000 |

0.17 |

52 |

660×820 |

1770×1180x1500 |

3500 |

||||||

|

1600 |

1170 |

14500 |

0.16 |

52 |

820x1070 |

1860x1240x1600 |

4130 |

||||||

|

2000 |

1360 |

18300 |

0.16 |

54 |

5.0 |

820x1070 |

1950x1320x1720 |

5420 |

|||||

|

2500 |

1600 |

21200 |

0.15 |

54 |

820×1070 |

2070x1400x1800 |

6500 |

Technical Parameters of 10kV Class S20, 22 Series Energy-saving Oil-immersed Transformer

|

Transformer |

High Voltage |

High Voltage Tap Range |

Low Voltage |

Rated |

Connection Group |

No-load Loss (W) |

Load Loss (W) |

No-load |

Noise |

Short Circuit |

Gauge |

Dimensions |

Weight |

||

|

S20 |

S22 |

S20 |

S22 |

||||||||||||

|

30 |

6 |

52× |

0.4 |

50 |

D,yn1 |

70 |

65 |

505/480 |

455/430 |

0.5 |

43 |

4.0 |

400×400 |

820x690×960 |

390 |

|

50 |

90 |

80 |

730/695 |

655/625 |

0.5 |

43 |

400x400 |

850x700x1000 |

580 |

||||||

|

80 |

115 |

105 |

1050/1000 |

945/900 |

0.45 |

44 |

400×400 |

890x750x1050 |

630 |

||||||

|

100 |

135 |

120 |

1265/1200 |

1140/1080 |

0.45 |

44 |

400×400 |

920×770x1070 |

680 |

||||||

|

160 |

180 |

160 |

1850/1760 |

1665/1585 |

0.4 |

46 |

550x550 |

1220×810x1140 |

900 |

||||||

|

200 |

215 |

190 |

2185/2080 |

1970/1870 |

0.4 |

47 |

550x550 |

1240×830x1180 |

1030 |

||||||

|

250 |

260 |

230 |

2560/2440 |

2300/2195 |

0.35 |

48 |

550×550 |

1300×860x1220 |

1210 |

||||||

|

315 |

305 |

270 |

3065/2920 |

2760/2630 |

0.35 |

48 |

660x660 |

1340×890x1290 |

1400 |

||||||

|

400 |

370 |

330 |

3615/3440 |

3250/3095 |

0.35 |

48 |

660x660 |

1370x920×1330 |

1620 |

||||||

|

500 |

430 |

385 |

4330/4120 |

3900/3710 |

0.3 |

49 |

660x660 |

1390x930x1400 |

1850 |

||||||

|

630 |

510 |

460 |

4960 |

4460 |

0.25 |

49 |

4.5 |

660x660 |

1500×970×1450 |

1960 |

|||||

|

800 |

630 |

560 |

6000 |

5400 |

0.18 |

50 |

660×820 |

1580x1010x1480 |

2620 |

||||||

|

1000 |

745 |

665 |

8240 |

7415 |

0.17 |

50 |

660x820 |

1700x1130x1530 |

2900 |

||||||

|

1250 |

870 |

780 |

9600 |

8640 |

0.17 |

52 |

660x820 |

1830x1240x1650 |

3600 |

||||||

|

1600 |

1050 |

940 |

11600 |

10440 |

0.16 |

52 |

820x1070 |

1900x1300x1720 |

4220 |

||||||

|

2000 |

1225 |

1085 |

14640 |

13180 |

0.16 |

54 |

5.0 |

820x1070 |

2700×2500×2500 |

5700 |

|||||

|

2500 |

1440 |

1280 |

14840 |

13360 |

0.15 |

54 |

820×1070 |

2800×2600×2600 |

6900 |

||||||

Note: Due to continuous product improvements, the data provided in this sample is for reference only; for the latest dimensions, please contact our company in time.

Recommended Products

Online message

Leave a message online and get a free product quotation. We will arrange a specialist to contact you as soon as possible