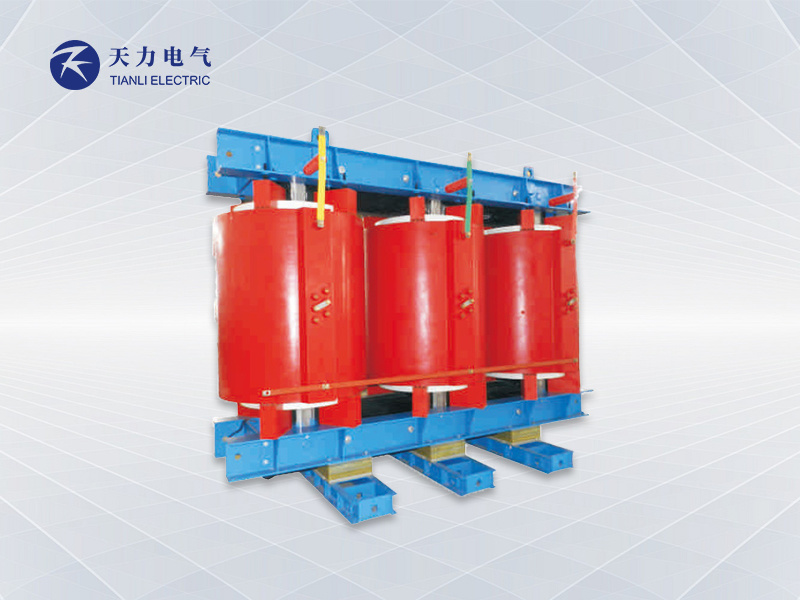

10KV class SGB series H-class insulation dry-type transformer

Category:

Keywords:

10KV class SGB series H-class insulation dry-type transformer

10kV class SGB series H-class insulation dry-type transformer

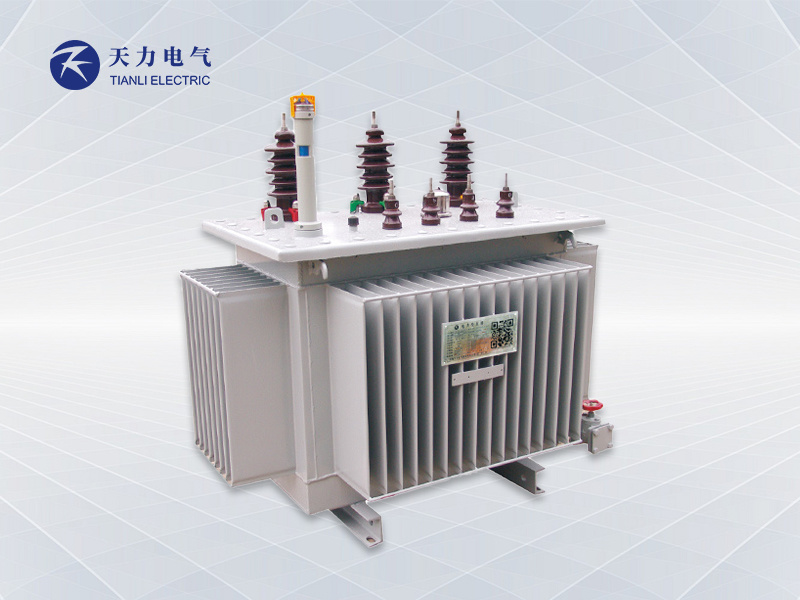

dry-type power transformer

dry-type power transformer

dry-type power transformer

dry-type power transformer

dry type transformer

1. Product Introduction:

This series of products is suitable for environments with high fire protection requirements, large load fluctuations, and harsh conditions such as dirt and humidity. Examples include airports, power plants, metallurgical operations, hospitals, high-rise buildings, shopping centers, densely populated residential areas, as well as special environments like petrochemical plants, nuclear power stations, and nuclear submarines.

2. Standards:

2.1 IEC60076-11 Dry-type power transformers

2.2 GB/T1094.1 Power transformers

2.3 GB/T1094.11 Dry-type power transformers

2.4 GB/T10228 Technical parameters and requirements for dry-type power transformers

2.5 JB/T10088 6kV~500kV power transformer noise level

2.6 GB20052-2020 Power transformer energy efficiency limits and energy efficiency levels

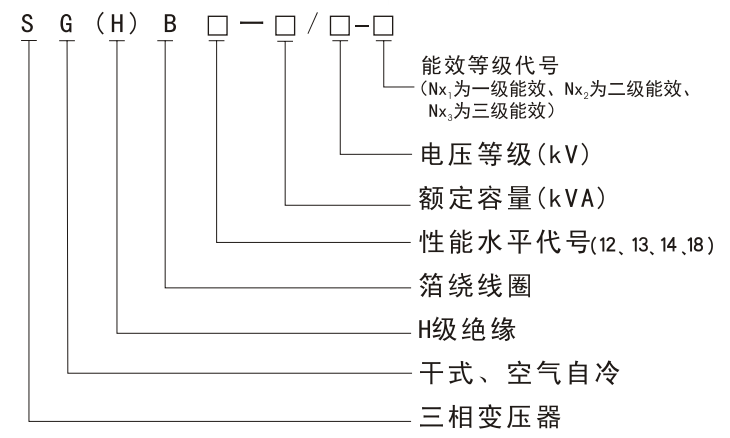

3. Model and Meaning:

4. Performance Features:

4.1 Good heat dissipation conditions, long thermal life, extremely strong overload capacity; can operate at 120% long-term overload under IP45 conditions without forced air cooling, allowing long-term full load operation.

4.2 Extremely high safety and flame retardant performance, producing no smoke under prolonged burning at 800°C.

4.3 Strong thermal shock resistance (can be fully loaded immediately at 50°C).

4.4 100% waterproof sealing, excellent water repellency and moisture resistance.

4.5 Unique winding structure and strong field calculation make the product almost free of partial discharge.

4.6 Low loss, significant energy-saving effect.

4.7 After the service life, insulation materials and copper wires can be easily separated and recycled without polluting the environment.

4.8 Equipped with remote monitoring function to grasp the equipment operating status in real time.

5. Structural Features:

5.1 Unique porcelain insulation structure, using MORA company's insulation tubes and high-frequency ceramic pads, never deforming.

5.2 High and low voltage windings use DuPont NOMEX insulation materials, and are impregnated multiple times with a special formula H-class insulating varnish using VPI vacuum pressure equipment, followed by multiple baking and curing. The high voltage winding adopts a continuous winding structure with high mechanical strength and good heat dissipation conditions.

5.3 The core material is made of high-quality silicon steel sheets with excellent magnetic conductivity, stacked in a 45-degree full-tilt structure. An elastic fixing device is used between the winding and the core, resulting in low no-load loss and noise. The core surface is treated with a special process. The core is moderately clamped by tie rods, with upper and lower clamps connected by tie plates and fixed integrally to the base. The winding is fixed by elastic pads, and the cushioning structure reduces winding vibration and noise.

5.4 The lead wire terminals are fixed on the upper part of the winding, the tap changer is in the middle of the winding, the low voltage lead terminals are plate-type conductive bars, and argon arc welding is used.

Technical Parameters of 10kV Grade SGB Series H-Class Insulation Dry-type Transformer

|

Transformer |

High Voltage (kV |

High Voltage |

Low Voltage |

Rated |

Connection Group Number |

No-load Loss (W) |

Load Loss (W) |

No-load Loss (W |

Load ) Loss (W |

No-load Loss (W |

Load Loss (W |

No-load |

Load |

No-load |

Noise |

Short Circuit |

Gauge |

Main Unit (excluding enclosure) |

Enclosure |

||

|

SGB12 |

SGB13 |

SGB14 |

SGB18 |

Overall Dimensions Length × Width × Height (m) |

Weight |

Overall Dimensions |

Weight |

||||||||||||||

|

160 |

6 |

;5 ;2× |

0.4 |

50 |

Dyn11 Yyn0 |

430 |

2280 |

385 |

2050 |

365 |

1915 |

310 |

1915 |

1.3 |

58 |

4 |

660×660 |

1180×720×1000 |

850 |

1600×1250×2200 |

250 |

|

200 |

495 |

2710 |

445 |

2440 |

420 |

2275 |

360 |

2275 |

1.1 |

58 |

660X660 |

1200×720×1050 |

930 |

1600×1250×2200 |

250 |

||||||

|

250 |

575 |

2960 |

515 |

2660 |

490 |

2485 |

415 |

2485 |

1.1 |

58 |

660×660 |

1250×720×1120 |

1080 |

1600×1250×2200 |

250 |

||||||

|

315 |

705 |

3730 |

635 |

3350 |

600 |

3125 |

510 |

3125 |

1 |

60 |

660×660 |

1280×720×1150 |

1250 |

1600×1250×2200 |

250 |

||||||

|

400 |

785 |

4280 |

705 |

3850 |

665 |

3590 |

570 |

3590 |

1 |

60 |

660×660 |

1300×720×1200 |

1450 |

1800×1450×2200 |

280 |

||||||

|

500 |

930 |

5230 |

835 |

4700 |

790 |

4390 |

670 |

4390 |

1 |

62 |

660×820 |

1380×880×1250 |

1750 |

1800×1450×2200 |

280 |

||||||

|

630 |

1070 |

6290 |

965 |

5660 |

910 |

5290 |

775 |

5290 |

0.85 |

62 |

660×820 |

1400×880×1300 |

2050 |

1800×1450×2200 |

280 |

||||||

|

630 |

1040 |

6400 |

935 |

5760 |

885 |

5365 |

750 |

5365 |

0.85 |

62 |

6 |

660×820 |

1480×880×1230 |

1900 |

1800×1450×2200 |

280 |

|||||

|

800 |

1210 |

7460 |

1090 |

6710 |

1035 |

6265 |

875 |

6265 |

0.85 |

64 |

660×820 |

1550×880×1300 |

2300 |

2000×1500×2200 |

350 |

||||||

|

1000 |

1410 |

8760 |

1270 |

7880 |

1205 |

7315 |

1020 |

7315 |

0.85 |

64 |

820×820 |

1620×880×1360 |

2750 |

2000×1500×2200 |

350 |

||||||

|

1250 |

1670 |

10300 |

1500 |

9330 |

1420 |

8720 |

1205 |

8720 |

0.85 |

65 |

820×820 |

1680×880×1460 |

3150 |

2000×1500×2200 |

350 |

||||||

|

1600 |

1960 |

12500 |

1760 |

11300 |

1665 |

10555 |

1415 |

10555 |

0.85 |

66 |

1070×1070 |

1720×1130×1560 |

3700 |

2200×1600×2200 |

380 |

||||||

|

2000 |

2440 |

15500 |

2190 |

14000 |

2075 |

13005 |

1760 |

13005 |

0.7 |

66 |

070×1070 |

1760×1130×1680 |

4300 |

2200×1600×2200 |

380 |

||||||

|

2500 |

2880 |

18400 |

2590 |

16600 |

2450 |

15445 |

2080 |

15445 |

0.7 |

71 |

1070×1070 |

1840×1130×1780 |

5100 |

2200×1600×2200 |

380 |

||||||

Note: Due to continuous product improvements, the data provided in this sample is for reference only; for the latest dimensions, please contact our company in time.

Recommended Products

Online message

Leave a message online and get a free product quotation. We will arrange a specialist to contact you as soon as possible